| IAS BIBO FILTER EQUIPMENT – BULLETIN DIRECTORY (Directory Ver 3, 10-2019) | |||

| Bul. No. | Version & No. | BULLETIN NAME | DESCRIPTION |

| 108 | 108-01-16 | (HOSPITAL) AIRBORNE ISOLATION ROOM FILTER SYSTEMS | A description of the CTC BIBO filter equipment and various accessories available. |

| 109 | 109-01-16 | INTERPRETATION OF CSA STD-Z317.2-15, AIRBORNE ISOLATION ROOMS | Like the title, this document is our interpretation of the CSA Z317.2-15, relating to the Airborne Isolation Room section. |

| 110 | 110-01-17 | B1-GASKET SEAL_CTC BIBO_SUGGESTED ENGINEERING SPECS | SUGGESTED ENGINEERING SPECIFICATIONS, B1-SERIES FILTER HOUSINGS/SYSTEMS |

| 111 | 111-01-17 | B2-GASKET SEAL_CTC BIBO_SUGGESTED ENGINEERING SPECS | SUGGESTED ENGINEERING SPECIFICATIONS, B2-SERIES FILTER HOUSINGS/SYSTEMS |

| 128 | 128-11-16 | HEPA FILTER DIFFERENTIAL PRESSURE TABLE & CURVES | Pressure curves for various models of HEPA and ULPA filters used in the CTC BIBO equipment. |

| 151 | 151-01-16 | INSULATION RECOMMENDATIONS FOR OUTDOOR BIBO EQUIPMENT | IAS recommendations for insulation of BIBO equipment when located outdoors (last resort location). |

| 155 | 155-01-10 | DECON PORTS-VALVES, VARIOUS TYPES | A brief description of the various decon ports/valves used on the BIBO filter equipment. |

| 170 | 170-12-16 | CTC FACTORY PRESSURE DECAY TEST PROCEDURE | TST-200, CONT. HOUSING TEST PROCEDURES |

| 172 | 172-10-17 | IN-SITU FILTER SYSTEM PRESSURE DECAY TESTING, N+1 REDUNDANT | Our arguments against specifying Pressure Decay Testing on BIBO equipment, especially N+1 systems and outdoor equipment. |

| 177 | 177-06-17 | AEROSOL INJECTION & SAMPLING PORT GUIDELINES, HEPA CHALLENGE-TESTING | A Guide for contractors having to install Aerosol Injection Ports. |

| 180 | 180-03-17 | STORAGE, RIGGING & INSTALLATION GUIDELINES, BIBO HOUSINGS | Storage, Rigging & Install Guidelines for BIBO’s |

| 182 | 182-1-13 | START-UP CHECKLIST | The IAS BIBO Start-up Checklist, used by installing contractors. |

| 183 | 183-11-16 | BIBO FILTER HOUSING, HEGA-HEPA FILTER START-UP GUIDE | A guide for installing contractors to ensure a safe and correct installation of the filters. |

| 185 | 185-01-17 | FILTER SERVICE CLEARANCE REQ’T (CTC O&M EXTRACT) | Recommendations for filter service clearance for BIBO equipment. |

| 191 | 191-01-10 | CTC O&M MANUAL, Ver 2010 | OEM O&M Manual from CTC, B1, B2 & C1 |

| 198 | 198-11-16 | N+1 REDUNDANT FILTER SYSTEM, SWITCHOVER PROCEDURE | A guide for hospital technicians maintaining BIBO filter equipment, particularly N+1 redundant filter systems. |

| 199 | 199-12-17 | OUTDOOR FILTER SERVICE CONSIDERATIONS | A guide for hospital technicians maintaining BIBO filter equipment that is located outdoors. |

| 201 | 201-11-16 | REDUNDANCY ARRANGEMENTS, BIBO HOUSINGS | A engineering guide. |

| 202 | 202-01-17 | REDUNDANT BIBO FILTER, SWITCHOVER MATRIX | A guide for hospital technicians maintaining BIBO filter equipment, particularly 2N redundant filter systems. |

| 218 | 218-01-17 | HEPA FILTER CHALLENGE ON N+1 FILTER SYSTEMS, OVERALL TEST METHOD | Explanation of IEST Overal Test Method wih multi-modules |

| 222 | 222-01-17 | IAS FILTER HOUSING START-UP REPORT (SAMPLE) | A sample of the start-up report IAS generates for their customers. |

| 309 | 309 | B1-SERIES HOUSINGS (CTC BROCHURE) | |

| 310 | 310 | B2-SERIES HOUSINGS (CTC BROCHURE) | |

| 311 | 311 | BUBBLE-TIGHT DAMPERS (CTC BROCHURE) | |

Bag-In/Bag-Out (BIBO) HEGA-HEPA Filtration

Bag-in/Bag-out (BIBO) Filter Systems are specialty side-access filter housings that permit the removal of the used air filters into a disposal bag. These heavy-duty disposal bags are mounted on collars underneath the filter access doors. When it’s time for filter change-out, the filter access doors are removed, exposing these seam-welded bags that are secured onto the door collars. An elaborate procedure is followed to remove the used filters and then replace the filters, all completed without exposing the contaminants within the filter housing, when it is done properly. The housings themselves are constructed of Type 304SS or 316SS, to ASME N509 Nuclear Standard. The standard describes the construction, welding procedures and materials allowed on these specialty housings.

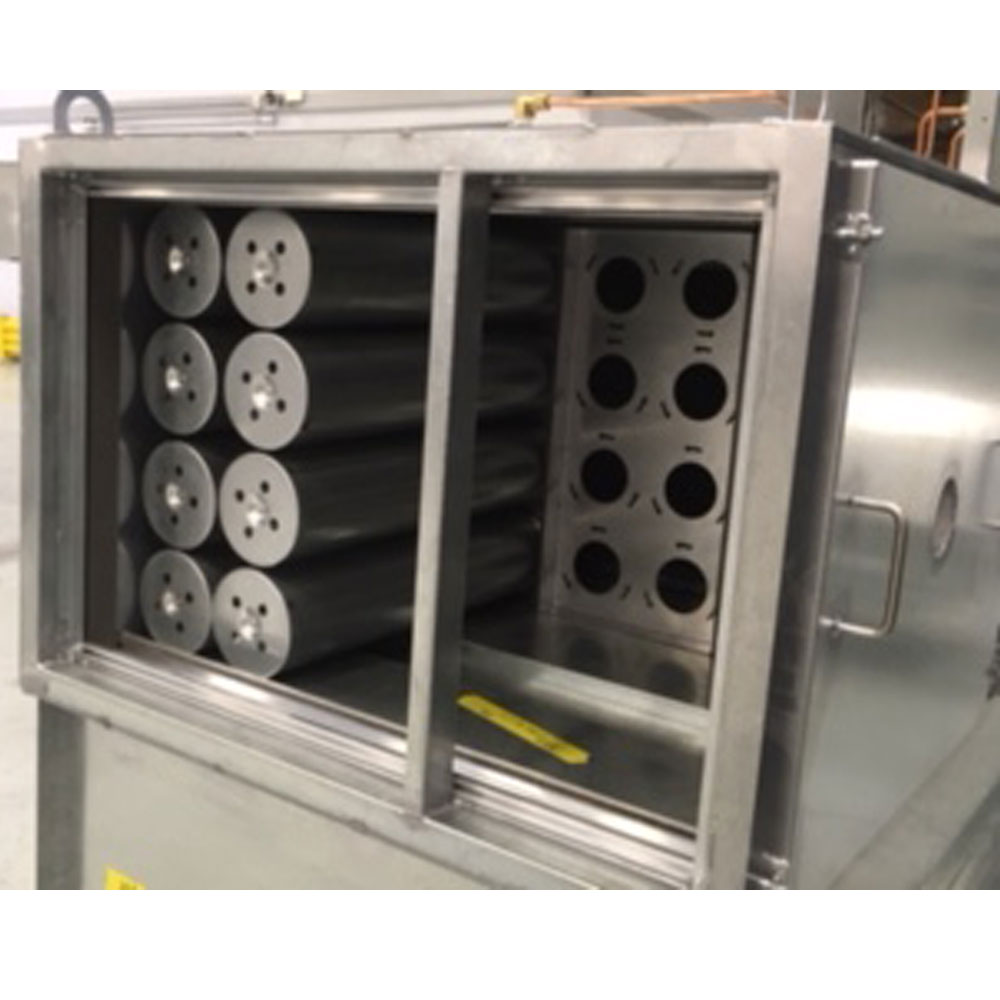

BIBO filter systems, by their nature, are used on critical applications where exposure to the dust, fumes or gases could be harmful (or possibly fatal) to service technicians. For that reason, these housings usually employ extremely high efficiency filters, such as HEPA (High-Efficiency Particulate Air), ULPA (Ultra-Low Penetration Air) or HEGA (High-Efficiency Gas-Phase Air) filter elements. Most BIBO filter systems are designed as multi-stage systems: Prefilter Stage(s), followed by HEPA/ULPA stage(s) and possibly HEGA filters (if there is a gaseous compound or radio-isotopes potentially in the gas-stream).

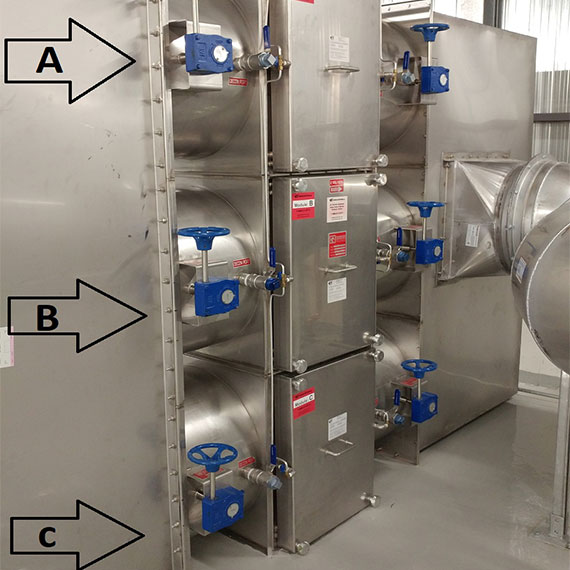

The BIBO system filter selections are dependent on the contaminants present and their concentration. Regardless of the contaminants, all filters are changed through the specialty bags, and all high-efficiency filters are sealed into the housing with heavy-duty clamping-mechanisms, to ensure there are no contaminants bypassing the filters. Often, these housings are provided with test apparatus to allow for the challenge of the various high-efficiency filters in the housing, all completed without any exposure to potential contaminants within the air stream. It is also very common to see bubble-tight dampers installed on the opposed flanges of the housing to permit isolation of the filter housing/module when filter change-out is completed.

There are many applications for Bag-in/Bag-out (BIBO) filter systems, including, but not limited to:

- HVAC Systems in Nuclear Power Generating Stations

- Fume Hoods and Extraction Fans removing toxic fumes (Heavy metals, etc.)

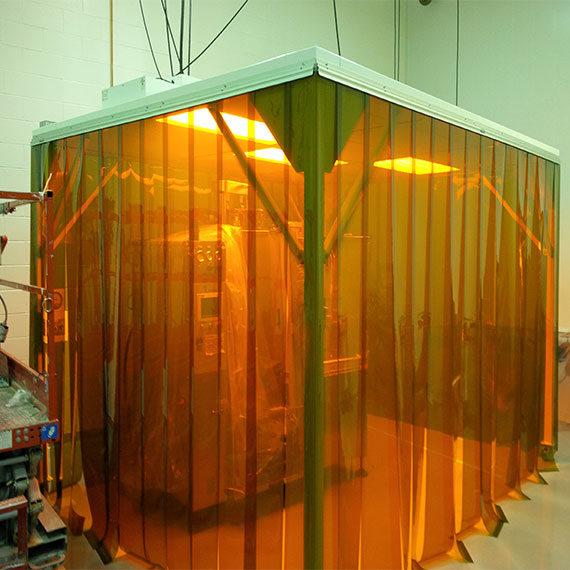

- Pharmaceutical applications such as Cytotoxic drugs, high-potency or active ingredient manufacturing & packaging, etc.

- Hospital Air Isolation Rooms (AIR’s), and other negative pressure procedural suites such as Brachytherapy, Endoscopy are performed, but the air cannot be exhausted without possible re-entrainment.

- Cyclotrons require specialty BIBO filter systems with HEGA filters